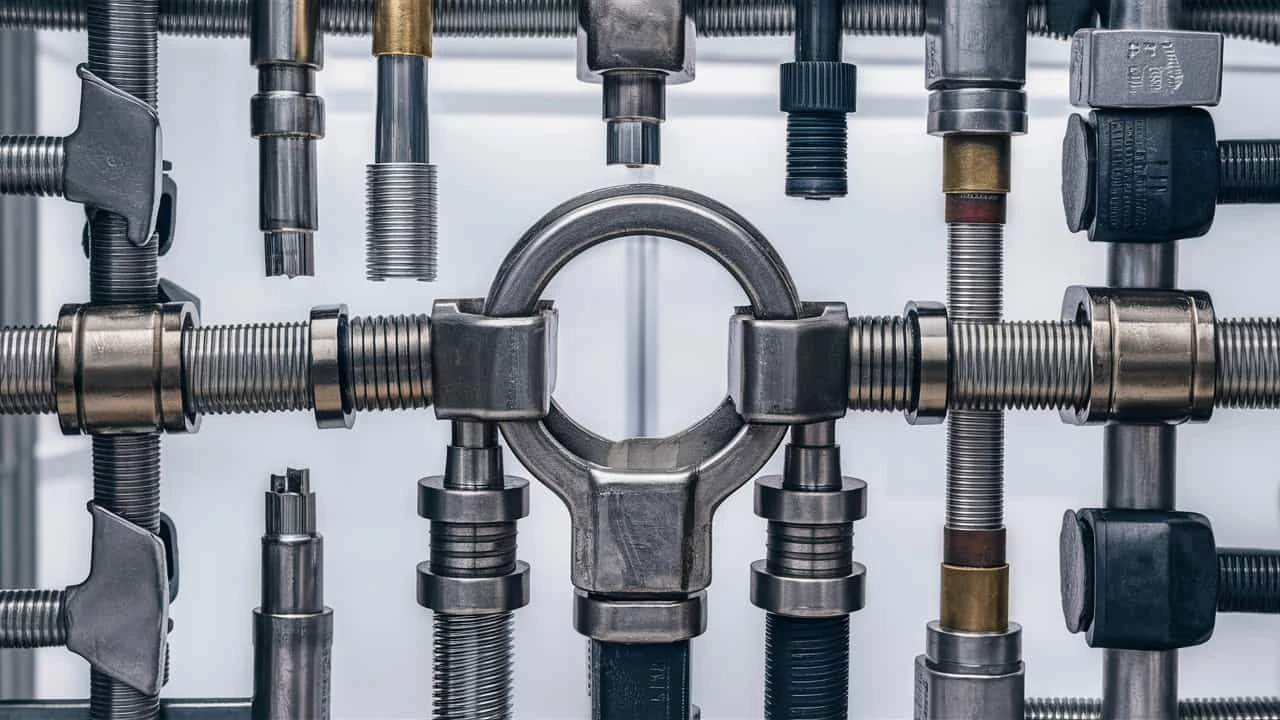

When dealing with fluid or gas transfer systems, ensuring the integrity of hose connections is crucial. One of the significant challenges faced in these systems is "cold flow," where the hose material deforms or shrinks over time due to temperature variations, leading to potential leaks. Hose clamps are essential in mitigating this issue by ensuring a firm and consistent seal. By maintaining a steady clamping pressure, they adapt to the changes in hose material, preventing gaps and leaks. But how do these **hose clamps** function, and what are the benefits of using them?

How Does Cold Flow Occur in Hose Connections?

Cold flow in hose connections occurs mainly due to the thermal expansion and contraction of materials. When a hose with clamp is exposed to temperature fluctuations, the hose material can soften and deform under pressure. As temperatures drop, it can shrink, creating gaps between the hose clamps and the hose, which leads to leaks.

Additionally, factors such as constant pressure and prolonged exposure to varying temperatures can further exacerbate cold flow. This makes the correct selection and application of hose clamps critical in industrial settings, where ensuring the reliability of fluid transfer systems is paramount.

* Cold flow can happen in both rubber and plastic hoses.

* It can compromise the system’s efficiency and cause fluid or gas leakage.

What Are the Consequences of Cold Flow in Hose Systems?

Cold flow, if left unchecked, can lead to several problematic outcomes in hose and clamps systems:

Leakage: The most immediate consequence is the potential for leaks, which can lead to system failure.

Maintenance Costs: Frequent adjustments or replacements of clamp hose may increase maintenance costs.

Safety Risks: Leaks can pose significant safety hazards, especially in systems carrying harmful chemicals or high-pressure gases.

Operational Downtime: Unexpected leaks can cause significant production delays.

Reduced Lifespan: Continuous cold flow can deteriorate the hose material, reducing the system's overall longevity.

Understanding these consequences highlights the importance of using effective hose clamps to mitigate the risks associated with cold flow.

How Do Constant Tension Hose Clamps Prevent Cold Flow?

Constant tension hose clamps are specially designed to adapt to the changes in hose material caused by temperature fluctuations. These hose clamp types maintain a constant clamping force by compensating for expansion and contraction.

* They prevent gaps from forming between the hose and clamps.

* They ensure a secure seal throughout the operating temperature range.

Moreover, constant tension hose clamps automatically adjust their clamping pressure, which reduces the need for manual interventions. This automatic adjustment capability is particularly beneficial in environments with frequent temperature changes, ensuring long-term reliability and system integrity.

How Do Constant Tension Hose Clamps Differ from Regular Hose Clamps?

Constant tension hose clamps stand out from regular hose clamps due to their ability to adapt to varying temperatures. Unlike traditional small hose clamps that may require manual adjustments, constant tension spring hose clamps automatically adjust their tension.

* Designed with special spring mechanisms to counteract material shrinkage and expansion.

* Ideal for applications where temperature variations are common.

Additionally, constant tension hose clamps provide a more flexible and dynamic response to thermal changes compared to regular hose clamps. The superior design and materials used in these clamps enhance their performance, ensuring a more reliable seal under varying conditions.

What Materials and Technologies Are Used in Constant Tension Hose Clamps?

Constant tension hose clamps are typically made from materials that provide both flexibility and durability.

Stainless Steel: Commonly used due to its resistance to corrosion and ability to maintain tension over time.

Special Spring Mechanisms: These mechanisms allow the clamp to expand and contract with the hose material.

Advancements in clamp technology have led to the integration of various high-performance elements:

Engineered Polymers: Some constant tension clamps incorporate high-performance polymers for added resilience.

Precision Manufacturing: Ensures consistent quality and reliability of the clamps.

Incorporating these materials and technologies ensures that constant tension hose clamps deliver optimal performance, even in demanding industrial settings.

What Are the Benefits of Using Constant Tension Hose Clamps in Cold Flow Prevention?

Utilizing constant tension hose clamps in systems susceptible to cold flow offers numerous benefits:

Improved Seal Integrity: The adaptive nature of these clamps ensures that the seal remains intact despite temperature changes.

Reduced Maintenance: Less frequent adjustments make these clamps easier to manage, reducing overall maintenance efforts.

Enhanced Safety: With a more consistent seal, risks related to leaks are significantly minimized.

Versatility: Suitable for a wide range of applications, from large hose clamps to small hose clamps, they can be used in various industrial settings.

Longer Lifespan: Reduces wear and tear on both the hose and clamps due to consistent pressure.

Operational Efficiency: Minimizes unplanned downtime and maintains steady system performance.