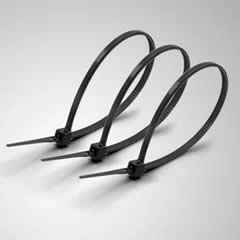

Standard Cable Ties

- Only high quality plastic that can be recycled in nature is used

- Wide variety of materials, sizes and colors

- High tensile strength with low application force

- Serrated inner surface to grip the application area more tightly

- Edge surface slope for easy application

- Easy application manually or with apparatus

Tork standard cable ties are produced from Polyamide 6.6 material, which is known as the most durable of plastics. It has high strength and hardness thanks to its semi-crystalline structure. These structural features make Tork standard cable ties the most suitable material to use under loads due to their very high bending and tensile strength and low friction coefficient.

Black-colored Tork cable ties provide excellent protection against sunlight with UV resistance in outdoor applications with the carbon black additive inside.

Features of Standard Cable Ties

TORK Standard Cable Ties come with a plethora of features designed to ensure ease of use and a strong hold. The high-quality, recyclable plastic is kind to the environment without compromising on quality. With a serrated inner surface for a tighter grip and an edge surface slope for simpler application, these cable ties are user-friendly, allowing for manual or tool-assisted application. Their black color, imbued with a carbon black additive, guarantees UV resistance, making them ideal for both indoor and outdoor applications.

Versatile Use Cases for Standard Cable Ties

Standard Cable Ties are designed for adaptability, making them a valuable asset across a plethora of industries. The electrical industry benefits from their secure bundling capabilities, ensuring safety and organization in wiring applications. In the realm of industrial cabling, their robust construction handles the rigorous demands of securing heavy-duty cables. The automotive industry utilizes these ties for their heat resistance and durability, essential for withstanding engine vibrations and temperatures. For renewable and non-renewable energy sectors, their reliability is crucial for long-term installations. Furthermore, in the building and construction fields, their UV resistance and tensile strength make them indispensable for outdoor projects. Our cable ties multifaceted applications highlight their necessity in diverse operational environments.

Standard Cable Ties: Sizes and Strength Specifications

Our comprehensive range of Standard Cable Ties is meticulously designed to accommodate a variety of bundling needs. With lengths extending from the compact 100 mm to the substantial 1200 mm, and widths from a slim 2.5 mm to a broad 9.0 mm, our inventory ensures the right fit for any job. The strip thickness and tensile strengths are calibrated to provide a secure hold, with specifications crafted to support from a modest 8 kg/f to an impressive 80 kg/f load. Each standard cable tie is rigorously tested to ensure a secure tighten range that upholds the integrity of your bundle. To cater to project scales both large and small, we offer diverse packaging options, from individual bags to bulk carton boxes, thus ensuring that you have the exact quantity required for your project's success.

Standard Cable Ties Technical Specifications

Raw material: Polyamide 6.6

Moisture Absorption: 2.7% (50% relative humidity)

Working temperature: -40 ° C + 85 ° C

Application temperature: -10 ° C + 60 ° C

Combustion degree: UL 94 class V2

Halogen free: Yes

Standard Cable Ties Application Areas

- Electricity Industry

- Industrial cabling

- Automotive

- Energy sector

- Building and construction sector

Standard Cable Ties Certifications