Heavy Duty Hose Clamp

1 – Its simple design ensures easy installation in usage areas.

2 – D nut helps to reduce the application force on the bolt and mechanical lock

3 – 360 degree balanced clamping force

4 – Durable design welded from three points

5 – Burr-free and convex band edge

TORK Heavy Duty Hose Clamps are designed for high torque and precise sealing at high pressure points. The clamp is especially used in pressure areas where precise sealing is required for thick and reinforced hoses. Its convex structure prevents the hose from being damaged and ensures a long life.

– High band tension and high tightening torque

– Durable compact design

– Quick and easy assembly

Heavy duty hose clamps are essential for securing hose connections in demanding environments where high strength and durability are paramount. These clamps are typically used in industrial, automotive, and marine applications, where they ensure a tight seal to prevent leaks under high pressure.

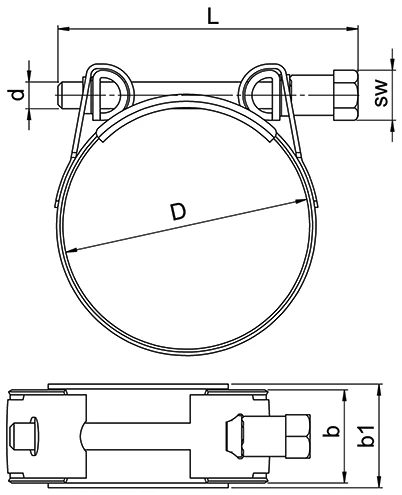

Heavy Duty Hose Clamp Specifications

Heavy duty hose clamps are designed to withstand rigorous conditions, making them suitable for a variety of challenging applications. Heavy duty stainless steel hose clamps offer superior corrosion resistance, making them an ideal choice for maritime and chemical processing environments. These clamps can handle pressure up to 250 psi, with bandwidths ranging from 12mm to 40mm, ensuring a robust and secure fit.

In terms of durability, heavy duty stainless hose clamps are manufactured with grade 304 or 316 stainless steel. This specification not only enhances their resistance to rust and corrosion but also ensures longevity even under extreme conditions. The design typically includes a solid band with a bolt mechanism, allowing for adjustable tightness and a reliable seal.

Sizes of Heavy Duty Hose Clamp

Choosing the correct size of heavy duty hose clamp is crucial for ensuring effective sealing and performance. These clamps are available in diameters ranging from ¼ inch to about 8 inches, accommodating a wide range of hose sizes. For specialized applications, custom sizes can be produced to meet specific requirements.

Each stainless steel heavy duty hose clamp is designed to provide a perfect fit, with minimal risk of damaging the hose due to overtightening. It's essential to select a clamp that matches the outer diameter of the hose to ensure effective use. Users should refer to a sizing chart or consult with manufacturers to select the appropriate clamp size for their particular application.

Technical Features Heavy Duty Hose Clamp

The technical features of heavy duty hose clamps are designed to provide high reliability and performance. One of the notable features is the non-perforated band design, which eliminates the risk of hose damage during installation and use. Heavy duty hose clamp types such as the T-bolt, worm drive, and V-band clamps offer different mechanisms to handle varying pressures and usage scenarios.

Stainless steel heavy duty hose clamps typically feature a welded construction, enhancing their strength and endurance. The tightening mechanism is engineered to distribute uniform pressure all around the hose, preventing any leaks while maintaining the integrity of the connection. This robust construction ensures that the clamp can maintain its grip even in conditions of thermal expansion and contraction.

Heavy Duty Hose Clamp Dimensions

Heavy Duty Hose Clamp Application Areas

- Commercial vehicle industry

- Irrigation systems

- Filters and pumps

- Maritime

- Construction machinery

- Engine manufacturing

- Mining industry

- Agricultural machinery

- Railway industry

- Ship manufacturing

- Chemical industry

- Machine building

- Food industry

- Generator

- Hose industry

Heavy Duty Hose Clamp Box Content

| Product Code | Diameter | Band Width Thickness | b1 | d*L | SW | Torpue Value | Quantity Pcs Box | |

| mm | inch | mm | mm | Min(Nm) | ||||

| AH018W1-017019-01 | 17-19 | 11/16 3/4 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH018W1-019021-01 | 19-21 | 3/4 - 13/16 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH018W1-021023-01 | 21-23 | 13/16 - 29/32 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH018W1-023025-01 | 23-25 | 29/32 1 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH018W1-025027-01 | 25-27 | 1 11/16 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH018W1-027029-01 | 27-29 | 11/16 - 15/32 | 18*0.8 | 20.0 | M6x52 | 8 | 10.0 | 200 |

| AH020W1-029031-01 | 29-31 | 15/32 - 17/32 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-031034-01 | 31-34 | 17/32 - 15/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-034037-01 | 34-37 | 1 5/16 - 17/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-037040-01 | 37-40 | 17/16 19/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-040043-01 | 40-43 | 19/16-111/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-043047-01 | 43-47 | 1 11/16 - 17/8 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 100 |

| AH020W1-047051-01 | 47-51 | 17/8 2 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 50 |

| AH020W1-051055-01 | 51-55 | 2 - 2 5/32 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 50 |

| AH020W1-055059-01 | 55-59 | 5/32 - 2 5/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 50 |

| AH020W1-059063-01 | 59-63 | 2 5/16 - 2 1/2 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 50 |

| AH020W1-063068-01 | 63-68 | 2 1/2 - 2 11/16 | 20*1.0 | 23.0 | M7x60 | 10 | 20.0 | 50 |

| AH025W1-068073-01 | 68-73 | 2 11/16 - 27/8 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-073079-01 | 73-79 | 27/8 - 3 1/8 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-079085-01 | 79-85 | 3 1/8 - 3 11/32 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-085091-01 | 85-91 | 3 11/32-3 9/16 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-091097-01 | 91-97 | 3 9/16-3 13/16 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-097104-01 | 97-104 | 313/16-4 3/32 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-104112-01 | 104-112 | 4 3/32 - 43/8 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-112121-01 | 112-121 | 4 3/8 - 43/4 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH025W1-121130-01 | 121-130 | 4 3/4 - 51/8 | 25*1.4 | 28.0 | M8x85 | 13 | 25.0 | 50 |

| AH030W1-130140-01 | 130-140 | 5 1/8 5 1/2 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-140150-01 | 140-150 | 51/2 - 57/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-150162-01 | 150-162 | 57/8 - 63/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-162174-01 | 162-174 | 6 3/8 - 67/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-174187-01 | 174-187 | 67/8 73/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-187200-01 | 187-200 | 7 3/8 - 77/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-200213-01 | 200-213 | 7 7/8 8 3/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-213226-01 | 213-226 | 8 3/8 - 87/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-226239-01 | 226-239 | 87/8 9 3/8 | 30*1.5 | 33,5 | M10x112 | 17 | 50.0 | 25 |

| AH030W1-239252-01 | 239-252 | 9 3/8 97/8 | 30*1.5 | 33.5 | M10x112 | 17 | 50.0 | 25 |

Heavy Duty Hose Clamp Producible Quality Types

| Band | Bolt | Nut | |

| W1 | DC01 – DIN EN 10130 | 1.0330 veya eşdeğeri | DD11 – DIN EN 10111 |