Perforated Hose Clamps

1 – The tightening range and standard number are indicated on the product

2 – Easy & safe assembly with improved cover and screw design

3 – Philips screw is advantageous over flat screws and is used by many factories and end users,

4 – Burr-free and convex edges preventing the hose from being damaged

5 – Triangular design that prevents the form from being distorted

TORK perforated hose clamps are engineered to provide a precise and economical solution for a wide range of general applications. They feature a tightening range and standard number clearly indicated on each product for ease of identification. The hose clamps are designed with user safety in mind, offering easy assembly thanks to an improved cover and screw design. The use of a Phillips screw provides an advantage over flat screws, being the preferred choice among many factories and end users for its secure fit and ease of use. Further ensuring the integrity of the hose, these clamps have burr-free and convex edges that prevent any potential damage during installation. Their triangular design is critical in maintaining the hose's shape, avoiding any distortion that could compromise the sealing. Combining all these features, TORK hose clamps fit perfectly on the hose and guarantee the best possible sealing of the connection, making them a popular and precise choice for various applications.

Perforated Hose Clamps Maintenance and Care

Perforated hose clamps require regular maintenance to ensure their longevity and optimal performance. Regular inspection is key; check for signs of corrosion, wear, or damage during routine maintenance checks. It's important to clean the clamps periodically to remove any debris or corrosive substances that could affect their function. When tightening or adjusting these hose clamps, use the correct tools and follow the manufacturer's torque specifications to avoid over-tightening, which can compromise the clamp’s effectiveness and damage the hose. If a clamp shows signs of damage, replace it immediately to maintain the integrity of the connection.

Perforated Hose Clamps Compatibility and Specifications

Choosing the right perforated hose clamp involves understanding its compatibility and specifications. These hose clamps come in various sizes and materials, each suited for different pressures, temperatures, and environmental conditions. Ensure that the clamp’s material is compatible with the substances it will contact, whether they are oils, gases, or corrosive chemicals. Additionally, check the diameter range of the clamp to ensure a snug fit around the hose or pipe. Specifications often include details like bandwidth, screw type, and maximum torque capacity, all crucial for matching the clamp to its intended application effectively.

TORK perforated hose clamps are designed for use in many general applications, they are popular, precise and economical.

The clamp fits perfectly on the hose and ensures the best sealing of the connection.

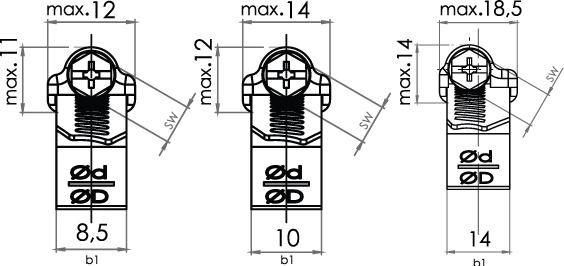

Perforated Hose Clamps Dimensions

Perforated Hose Clamps Application Areas

- Hardware

- Household appliances

- Agriculture

- Gas Filled Bottles

- LPG – Autogas Systems

- Building Sector

- Mechanical Applications

- Solar Energy Systems

- Signalization Systems

Perforated Hose Clamps Box Content

| Product Code | Diameter | Band Width | Band Thickness | Max. Torpue Resistance | Pcs inside box | |

| mm | inch | mm | mm | Nm | ||

| HR085W1-008012-101 | 8-12 | 5/16" 1/2" | 8.5 | 0.60 | 2.5 | 1.000 |

| HR085W1-010016-101 | 10-16 | 3/8" 5/8" | 8.5 | 0.60 | 2.5 | 1.000 |

| HR085W1-012020-101 | 12-20 | 1/2" 3/4" | 8.5 | 0,70 | 4.0 | 1.000 |

| HR085W1-013019-101 | 13-19 | 1/2" 3/4" | 8.5 | 0.70 | 4.0 | 1.000 |

| HR085W1-016025-101 | 16-25 | 5/8" 1" | 8.5 | 0,70 | 4.0 | 1.000 |

| HR010W1-019026-101 | 19-26 | 3/4" 11/3" | 10 | 0.80 | 5.0 | 1.000 |

| HR010W1-020032-101 | 20-32 | 3/4" 11/4" | 10 | 0.80 | 5.0 | 1.000 |

| HR010W1-023035-101 | 23-35 | 8/9" 11/4" | 10 | 0.80 | 5.0 | 800 |

| HR010W1-025040-101 | 25-40 | 1" 15/8" | 10 | 0.80 | 5.0 | 700 |

| HR010W1-028048-101 | 28-48 | 13/32" 1" | 10 | 0.80 | 5.0 | 600 |

| HR010W1-030045-101 | 30-45 | 7/8" | 10 | 0.80 | 5.0 | 600 |

| HR010W1-032050-101 | 32-50 | 11/6" 13/4" | 10 | 0.80 | 5.0 | 600 |

| HR010W1-040060-101 | 40-60 | 11/4" 2" | 10 | 0.80 | 5.0 | 400 |

| HR010W1-044064-101 | 44-64 | 15/8" 2" | 10 | 0.80 | 5.0 | 400 |

| HR01OW1-050070-101 | 50-70 | 3/8" | 10 | 0.80 | 5.0 | 400 |

| HR01OW1-060080-101 | 60-80 | 13/4" 2" | 10 | 0.80 | 5.0 | 300 |

| HR01OW1-070090-101 | 70-90 | 1/2" | 10 | 0.80 | 5.0 | 100 |

| HR010W1-080100-101 | 80-100 | 2" 2 3/4" | 10 | 0.80 | 5.0 | 100 |

| HR010W1-090110-101 | 90-110 | 2 3/8" 3" | 10 | 0.80 | 5.0 | 100 |

| HR010W1-100120-101 | 100-120 | 1/8" | 10 | 0.80 | 5.0 | 50 |

| HR010W1-110130-101 | 110 - 130 | 4 4/3 5 1/8 | 10 | 0.80 | 5.0 | 50 |

| HR010W1-120140-101 | 120-140 | 1/2" | 10 | 0.80 | 5.0 | 50 |

| HR010W1-130150-101 | 130-150 | 3 1/8" 4" | 10 | 0.80 | 5.0 | 50 |

| HR010W1-140160-101 | 140-160 | 3 1/2 4" | 10 | 0.80 | 5.0 | 50 |

| HR01OW1-150170-101 | 150-170 | 3/8" | 10 | 0.80 | 5.0 | 50 |

| HR01OW1-160180-101 | 160-180 | 4" 4 3/4" | 10 | 0.80 | 5.0 | 50 |

| HR01OW1-170190-101 | 170-190 | 4 3/8" 5" | 10 | 0.80 | 5.0 | 40 |

| HR010W1-180200-101 | 180-200 | 1/8" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-190210-101 | 190-210 | 4 3/4" - 5" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-200220-101 | 200-220 | 1/2" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-210230-101 | 210-230 | 5 1/8" 5" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-220240-101 | 220-240 | 7/8" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-230250-101 | 230-250 | 5 1/2" 6" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-240260-101 | 240-260 | 1/4" | 10 | 0.80 | 5.0 | 25 |

| HR010W1-250270-101 | 250-270 | 5 7/8" 6" | 10 | 0.80 | 5.0 | 25 |

Perforated Hose Clamps Producible Quality Types

| Bands | Covers | Screws | Corrosion resistance | |

| W1 | 1.0330 or equivalent | 1.0330 or equivalent | 1.0263 or equivalent | 72 hours |

| W2 | 1.4016 or equivalent | 1.4016 or equivalent | 1.0263 or equivalent | 144 hours |

Quality Standard: DIN 3017 ve TS12091

Environment: Does not contain chromium VI. Compliant with ROHS, WEEE and ELV Environmental Directives